How to Maximize Your Trenchless Technology Toolbox

Most sanitary collections systems around the United States were built between the 1940s and 1970s, which means they are not only undersized for growing communities but are reaching the end of their service life. During periods of high demand, such as during rain events, inflow and infiltration (I&I) can overload these systems, leading to backups, sanitary sewer overflows, and environmental pollution.

Retrofitting and upgrading these systems, especially through traditional methods like open-cut excavation, can be costly, time-consuming, and disruptive to the community. This is where it pays off to have a full toolbox of trenchless technology methods at your disposal. Cured-in-place-pipe (CIPP), pipe bursting, sliplining, and pipe ramming all offer ways to rehabilitate this underground infrastructure with minimal excavation, which decreases cost and disruption to the surrounding environment. But to maximize the benefits of trenchless technology, you must take a holistic approach—understanding the complexity and quirks of a collection system and when traditional methods are the best tool for the job.

A case study in the successful application of this toolbox, a multi-year I&I Abatement Program for the City of St. Helens, Oregon, resulted in both reduced sanitary sewer overflows and treatment plant costs. The following sections cover how this trenchless toolbox was directly applied to the St. Helens project.

Taking a holistic approach to addressing inflow and infiltration.

A comprehensive and integrated approach to addressing I&I is necessary because it is caused by a variety of factors (and exacerbated by increasingly common severe wet weather), including cracks or defects in pipes and manholes, improper connections, and aging infrastructure.

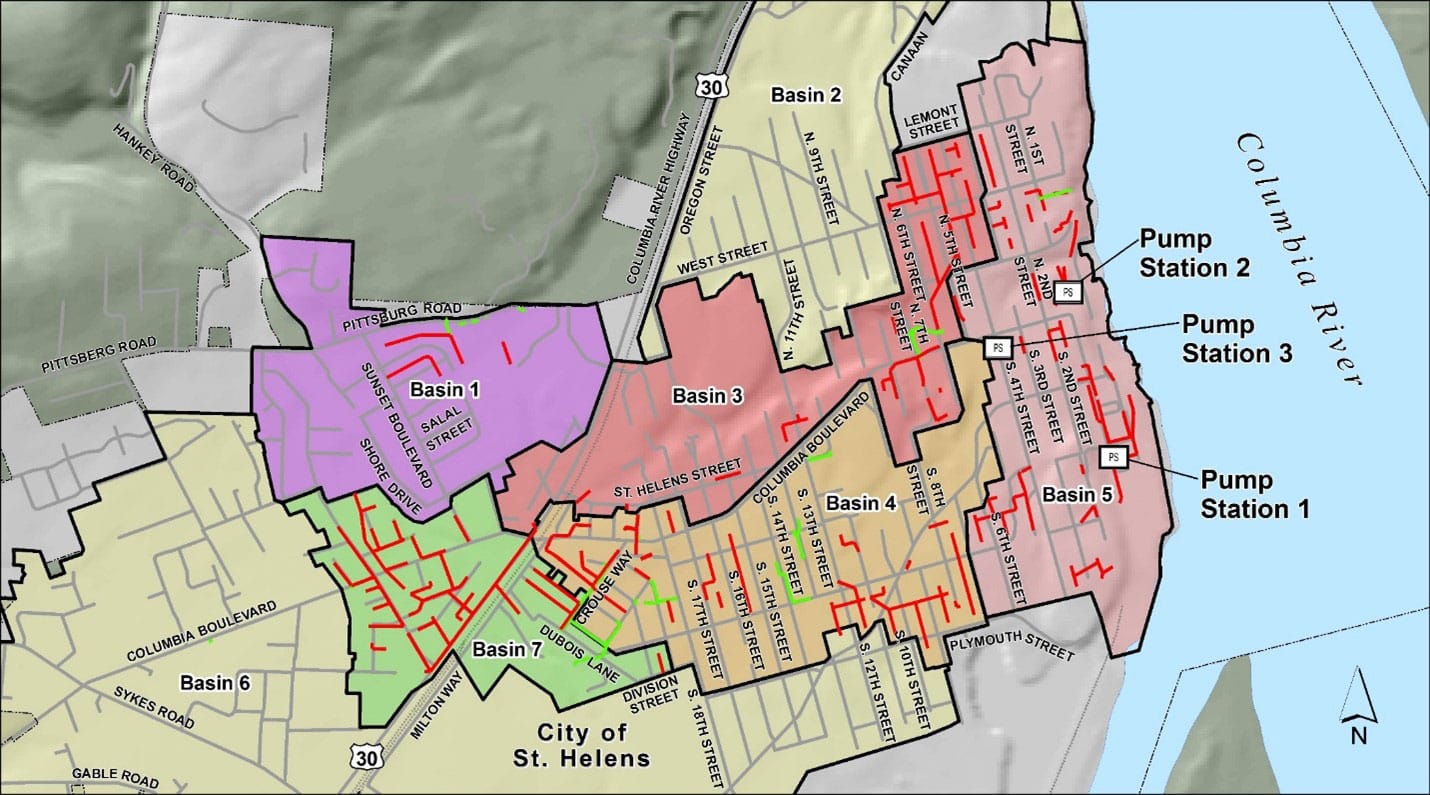

The City of St. Helens experienced this diversity of issues. With a population of roughly 14,100 people, the community is located on the bank of the Columbia River, approximately 30 miles northwest of Portland, Oregon. The city’s geologic conditions are unique, as it sits on shallow bedrock of hard basalt that has an estimated compressive strength of more than 40,000 psi. Due to the presence of the hard bedrock, the city’s infrastructure is relatively shallow, and the ground has very low infiltration rates. This leads to perfect conditions for I&I into deficient sewers.

St. Helens’s I&I Abatement Program began in the early 2000s when the Oregon Department of Environmental Quality (DEQ) mandated they pass the 5-year, 24-hour winter storm event and 10-year, 24-hour summer storm event without sanitary sewer overflows. As the first step in meeting the mandate, the City commissioned a flow study in 2005 that revealed three key details:

- The hydraulic capacity of the system was less than what would be required to handle the base flow plus rainfall-dependent I&I resulting from a 1.5-year rainfall event.

- The 5-year, peak-hour event produced a flow of 25 million gallons per day (mgd), of which 24 mgd was attributed to I&I.

- Basins 3, 4, and 5 contributed the largest amount of I&I flow.

In 2008, the City began to implement the I&I Abatement Program, which was designed to holistically address sanitary sewer deficiencies on both public and private property. The program had four main goals:

- Reduce the number of overflow events.

- Restore the capacity in the sanitary sewer system for future use.

- Improve existing storm sewers and install new storm sewers to eliminate flooding, as well as convey the stormwater flows diverted from the sanitary sewer system.

- Provide the maximum improvement value by focusing on the largest basin contributors of I&I.

Evaluating the right trenchless technology tools for the job.

Identifying the right approach starts with developing a robust understanding of the system’s condition and factors like mechanism of failure, geology, geographic accessibility, and property ownership.

Design efforts for Phases 1 and 2 of the City of St. Helens I&I Abatement Program began in 2008 with a condition assessment of existing assets and evaluation of CCTV inspection data. CCTV inspections primarily looked at the basins identified as the largest I&I contributors in a flow monitoring study, which focused available resources on the most deficient portions of the sanitary system, providing the most cost-effective reduction of I&I flows.

The pipes were evaluated to identify the extent and severity of deficiencies (i.e., root intrusion, separated joints, cracked pipe, and offset joints), objectively determine their condition, and identify the rehabilitation needs. Then potential rehabilitation methods were evaluated to select the most appropriate option for each pipe segment.

CIPP, your go-to trenchless tool.

CIPP is one of the most common trenchless technology methods. Based on St. Helens’s pipeline condition and accessibility, this rehabilitation method was the most widely used. CIPP involves inserting a flexible liner, typically made of resin-saturated felt or fiberglass, into the existing pipeline and curing it in place with UV light, hot water, or (as was used for St. Helens) steam. The result is a new, structurally sound pipe that conforms to the shape of the old pipe.

CIPP is often used when the existing pipe is damaged but still structurally sound, such as in cases of leaks, cracks, or corrosion. Compared to other trenchless methods, CIPP is generally considered more cost-effective, faster, and less disruptive to the surrounding area. However, it may not be suitable for all pipe diameters or conditions, and the quality of installation can be affected by factors such as temperature, humidity, and cleanliness of the pipeline.

Pipe bursting, your next trenchless tool that’s surprisingly non-destructive.

When pipeline conditions are not conducive to repair using CIPP (i.e., poor structural condition or undersized for the current flow rate), that’s when pipe bursting can come in. The City of St. Helens opted for this method on significantly damaged sections of pipe. Like CIPP, pipe bursting is particularly useful when impacts to the ground above the pipeline must be lessened or eliminated.

Minimizing the need for extensive excavation, pipe bursting involves creating a small access pit at each end of the pipeline segment that needs to be replaced, then pulling a new pipe through the existing pipeline behind a bursting head. The old pipe is broken apart and displaced into the surrounding soil. The new pipeline can be larger than the original, adding capacity, and made of various materials, including high-density polyethylene (HDPE), polyvinyl chloride (PVC), or ductile iron.

With St. Helens’s geologic conditions, and the position of pipelines spanning private properties, performing an analysis of displacement forces was critical to evaluating the risk of damage to existing surface structures, adjacent foundations, or utilities during the pipe bursting operation.

Sometimes traditional open-cut excavation methods are the right tool for the job.

There are several situations where traditional open-cut excavation may be preferred over trenchless methods. When the existing infrastructure is severely deteriorated or collapsed, it may not be possible to rehabilitate using trenchless methods. When access to the infrastructure is unrestricted and impacts to community are minimal, open-cut excavation can be preferred. Finally, certain soil conditions, such as rock or very dense soils, are not compatible with some trenchless methods.

The St. Helens project strategically applied open-cut methods when access or soil conditions made it more efficient and economical. For example, open-cut was the best solution for most of the later connections—a significant source of infiltration into a sanitary sewer system. For CIPP-rehabilitated lines within hardscaped areas, a trenchless method was used to reinstate the lateral connections robotically and then using an ultra-low viscosity chemical grout used to fill voids and seal the sewer connection. For most lateral connections, however, the shallow nature of the sewer system made it more efficient to use open-cut excavation to make new, watertight lateral connections directly into the installed mainline CIPP or HDPE pipe and replace the deficient lateral joints. The lateral connections were performed the same day as the CIPP installation to minimize the service interruption to the residents and businesses.

A full trenchless technology toolbox.

With the full trenchless toolbox, agencies facing an array of challenges have the tools to address sewer system deficiencies strategically and holistically. For the City of St. Helens, this resulted in accomplishing all goals set forth at the onset of the I&I Abatement Program within the available budget (just under $9.1M). The rehabilitation of approximately 12 miles of the City’s 57 miles of sanitary sewer mainlines and other improvements have resulted in an 80% reduction in sanitary flows pumped to the treatment plant from the three pump stations within the program area during wet weather events. Additionally, the number of sanitary sewer overflow events were drastically reduced; the City experienced an average of 2.5 sanitary sewer overflow events each year between 1995 and 2009, and between 2010 and 2017 the number of overflow events experienced dropped to less than 1.0/year. Since the completion of Phase 3 of the Mainline Program (a storm sewer and outfall upsizing project utilizing pipe ramming and open cut installation methods), the capacity issues have been resolved—there have been no reported overflows of the storm sewer in the upstream basins.