No One-Size-Fits-All Reservoir Solutions

Water storage reservoirs are vital to every community’s water system. They help meet peak demand, provide reliable fire flows, and supply emergency reserves during service interruptions. These facilities should be robustly designed and constructed and be maintained regularly to keep them performing this important role.

Selecting the right water storage reservoir type shapes long-term operations and maintenance. This decision also influences project costs, lifespan, and overall reliability.

While some engineers have a preferred reservoir type or types and provide limited options for their clients, our approach includes offering tailored solutions where all reservoir options are evaluated. This approach delivers the best results for communities’ priorities, budgets, site conditions, and long-term goals. Consor’s team of engineers draw on expertise based on the full range of reservoir types.

Key Factors Influencing Reservoir Type Selection

A water system owner weighs several factors when selecting a reservoir type, including:

- Capital and Lifecycle Costs: Based on available capital budget, owners may consider both life cycle cost vs capital cost. Some owners have the capital for a more expensive reservoir type upfront, reducing maintenance or repainting down the road. Others might choose a more economical option initially, knowing they’ll face more frequent maintenance cycles later.

- Maintenance: The ability to take a reservoir out of service for maintenance and owner’s diligence relative to up-keep impacts operational planning, including the frequency of future maintenance. For example, steel tanks, which need periodic recoating and corrosion protection, require more shutdowns for maintenance painting than concrete reservoirs, which don’t require recoating. Their long-term durability reduces the need for major repairs, making them a lower-maintenance option for many utilities. Additionally, certain types of elevated reservoirs include concrete pedestals, which don’t require repainting every 20-30 years, reducing maintenance costs and increasing sustainability.

- Geotechnical and Site Conditions: Topography, soil conditions, groundwater levels, and required reservoir elevation can guide decisions. For example, some reservoir types are more forgiving to potential differential settlement of soils under the tank. Some reservoir types are also more compatible with a sloped site or can be buried or partially buried to integrate the structure into the site’s topography.

- Water Quality and Operations: Reservoir height, shape, and internal configuration can affect turnover rates and water quality. Dead storage, or water in the lower portions of a reservoir that is not usable to provide the required system pressures, may not be regularly cycled through the system. This can lead to stagnation and reduced disinfectant levels in the water. Stored water is more easily mixed in round reservoirs compared to rectangular facilities, helping prevent temperature stratification and the buildup of disinfectant byproducts. Elevated reservoirs also reduce dead storage compared to welded steel standpipes. Proper mixing provides uniform water quality by keeping disinfectant levels consistent and preventing areas of stagnant water where contaminants or bacteria could develop.

- Community and Environmental Impacts: Owners often consider aesthetics, neighborhood opinions, and regulatory constraints. A reservoir type that blends into the landscape or reduces visual impacts may earn greater community support.

Reservoir Types

Through close collaboration with owners and operators, our engineers effectively evaluate reservoir types based on the factors outlined above to deliver customized solutions. Examples of common reservoir types and their advantages and key features are discussed below.

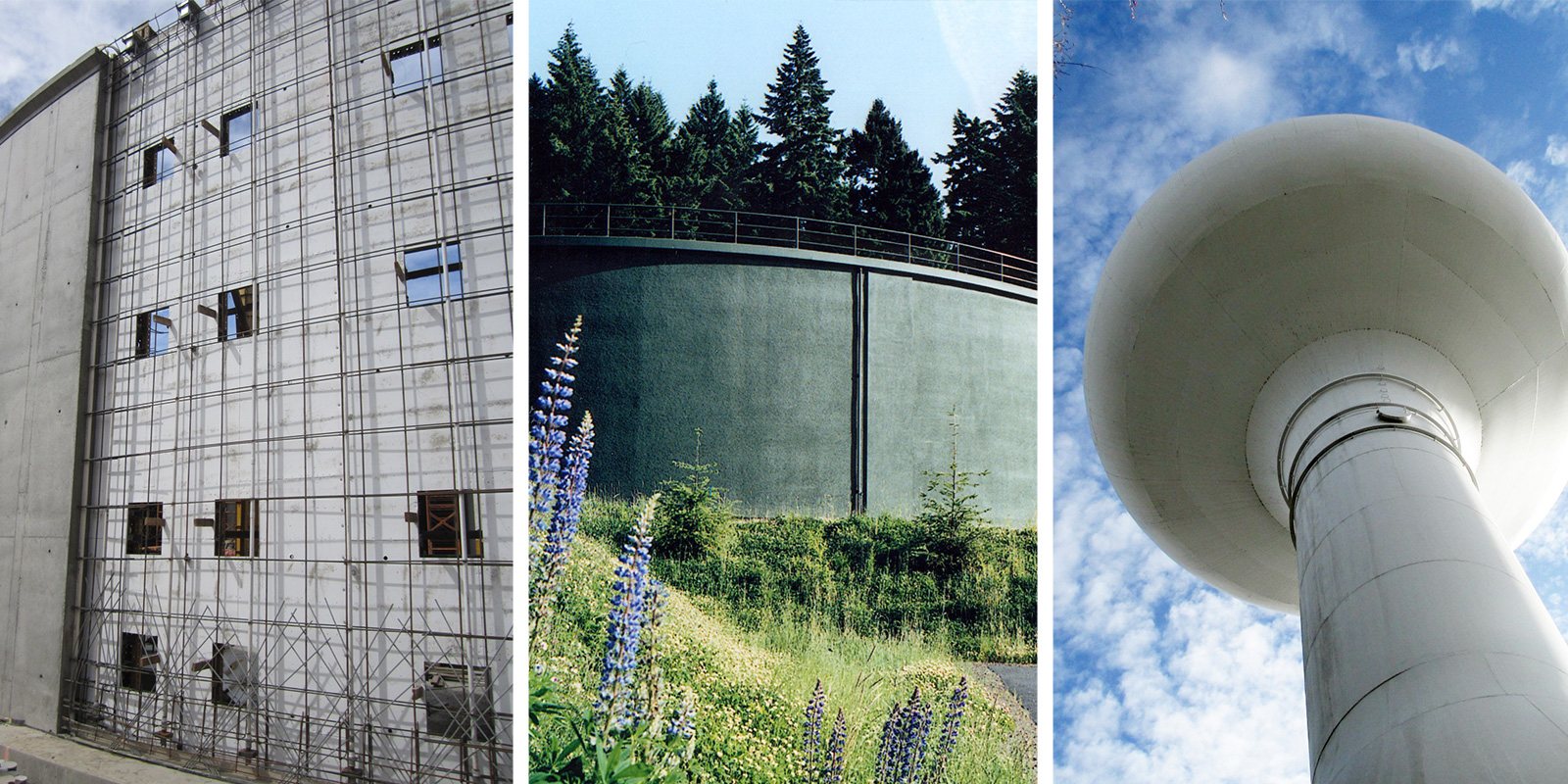

Prestressed Concrete Reservoirs

Prestressed concrete reservoirs can be robust and designed to last 100 years with moderate levels of maintenance on a cycle of 30 to 50 years. They don’t require painting, which is a common recurring maintenance activity on steel reservoirs. If designed and constructed properly, they experience minimal corrosion or other deterioration issues.

These structures can be readily buried or partially buried, which allows for site versatility. But because they can be more sensitive to geotechnical conditions under the reservoir, proper subsurface investigations and close coordination with the geotechnical and structural engineers is required during design.

There are a handful of different types of concrete reservoirs available to owners to select based on a number of factors. For example, owners in lower seismic areas often select one type of prestressed concrete tank, while in the more seismically active areas, like the Western United States, a more robust type is typically selected.

Operational needs and lower maintenance costs drove reservoir type selection for a small community.

A city north of Portland, Oregon, had operated a 0.75 MG welded steel reservoir for 30 years. However, when they required a new 1 MG reservoir to serve their growing community, the operators were not in favor of another facility that needed maintenance painting, which would require the reservoir to be taken offline. The city was, therefore, willing to spend more capital budget for a prestressed concrete reservoir on the site. The result was less maintenance and long-term savings on the life-cycle costs for the facility.

Welded Steel Ground Level Reservoirs

Provided the site can accommodate a completely above-ground structure, welded steel reservoirs can be a cost-effective option. These structures are typically lower cost at first than prestressed concrete reservoirs but do require more routine maintenance.

For example, the reservoir coating system typically needs to be replaced every 25 to 30 years, which often includes replacing the interior coating and overcoating the exterior or replacing the exterior coatings. These structures can also last 100+ years if designed and constructed properly and maintained regularly with quality coating systems. Current practices include using zinc primers on the interior below the water line, which provides longer coating service life and reduces long-term maintenance costs. With over 30 years of experience, Consor is a leader in long-lasting, low-maintenance coating systems for reservoirs.

Site conditions assessment and siting evaluation resulted in a reservoir type selection that met unique project needs.

A community on the Oregon Coast needed a 4 MG reservoir to serve as a contact basin and provide gravity flow from the existing clear well at their water treatment plant (WTP). The initial siting included a buried concrete reservoir near the WTP, but geotechnical investigations showed high groundwater as a result of permeable soils and a nearby water impoundment (dam and open reservoir). Consor analyzed alternatives and identified a new location on the site with the right elevation to allow for gravity feed to a ground-level reservoir. This new site orientation allowed the owner to select a welded steel reservoir, which simplified construction and saved capital costs without compromising service.

Welded Steel Standpipes

With heights greater than their diameters, standpipes offer the elevation needed to provide pressure to systems in topographies that lack natural high points. Standpipes can be lower cost up front than elevated reservoirs, but their large surface areas that require coating upgrades or replacements around every 30 years add substantial maintenance costs.

Because of the reservoir’s elevation, the lower 1/2 to 2/3 of the water storage doesn’t provide the required pressure to serve the system, creating “dead storage” (water that is not regularly used in the system), which can result in water quality challenges.

Alternative reservoir types were selected at two sites to meet storage needs while reducing neighborhood impacts.

A Southwest Washington community needed to replace two welded steel standpipes, which didn’t meet storage needs and required high-cost for seismic upgrades. Looking to maximize storage at the site, the owner requested Consor assess the feasibility of constructing two large elevated reservoirs or standpipes. The findings showed that two 2.5 MG elevated reservoirs would provide the lowest life cycle cost, best performance, and highest water quality. However, concerned with permitting through the County and potential neighborhood impacts, the owner found another site that would allow for a large composite elevated reservoir to meet storage requirements. Balancing the need for additional storage and costs, the owner also opted for the construction of one 2 MG standpipe at the current site. Consor is currently providing designs for facilities at both sites.

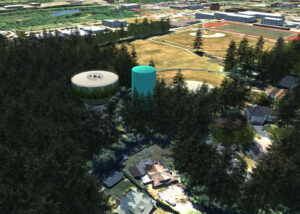

Elevated Reservoirs

Like standpipes, elevated reservoirs provide water at the needed elevation when natural high points are not available in the service area to feed the system. Elevated reservoirs eliminate the “dead storage” associated with standpipes. Also, because of reduced surface area that requires coating maintenance, they can have lower life cycle costs.

The options for elevated reservoirs include composite elevated (concrete pedestal with welded steel elevated water containing element), fluted tower (steel pedestal and steel water containing element), multi-legged, and spheroids. Recently, we’ve been seeing owners select composite elevated reservoirs because they offer lower coating maintenance costs paired with overall aesthetics.

Two different elevated reservoir types allowed during bidding reduced the cost for a community.

A Northwest Washington community was getting its water from two standpipes, which required significant maintenance and could not provide the desired pressure for the homes at higher elevations. To address these issues and meet growing demand, the owner asked Consor to review options for a new elevated reservoir or standpipe. During the design process for an elevated reservoir, the owner decided to allow two types of elevated reservoirs—composite and fluted tower—for which contractors to provide bids. The owner awarded the bid to the team proposing a fluted tower, as it was the lowest first cost.

Other Reservoir Types

While the reservoir types discussed above are most commonly specified for water systems, others may be preferred for certain applications. Less common reservoir types may be chosen for capital cost, facility size and criticality, owner preference or familiarity, or local contractor expertise.

For concrete reservoirs, a conventionally reinforced reservoir may be selected over a prestressed reservoir because of lower first cost, though the facility may not be as water-tight or low maintenance. For steel reservoirs, a bolted steel structure may be an option for facilities that are smaller, are less critical in the system, or must be constructed quickly. These often have lower up-front costs than welded steel reservoirs but may require replacement after 30+ years of service rather than maintained like welded steel facilities.

The reinforced concrete reservoir type was selected to save cost and minimize visual impact for a small water storage facility.

A Pacific Northwest community needed to replace a 100,000-gallon rectangular, conventionally reinforced concrete reservoir that was almost 100 years old. Located in a nature park, the reservoir needed to be fully buried to minimize visual impact and meet permitting requirements. Because it had to be buried, a concrete reservoir was the only option. At just 130,000 gallons, the new reservoir was small, so the owner decided on a conventionally reinforced facility that would be lower cost than prestressed concrete. The conventionally reinforced reservoir provided the needed upgrade following some minor crack sealing in the walls, which is expected from this reservoir type.

Reservoir Selection Success

Selecting the right type of reservoir means optimizing water system operations, improving water quality, minimizing community impacts, and managing budgets and long-term maintenance costs. A well-designed reservoir not only provides long-term value for the owner but results in excellent, reliable service for their customers.

A one-size-fits-all approach to reservoir design overlooks unique site conditions, operational needs, and community priorities, ultimately diminishing long-term value and efficiency. Consor’s reservoir engineers understand the complexities and costs of each reservoir type. Investing the time and energy to collaborate with client teams and operators helps us get at the nuances of the decision-making process and advise on solutions that best fit their specific needs and budgets.

For owners considering adding a new reservoir or upgrading an existing reservoir, contact me, and I’ll bring together Consor’s reservoir experts to answer questions and provide guidance on reservoir type selection.